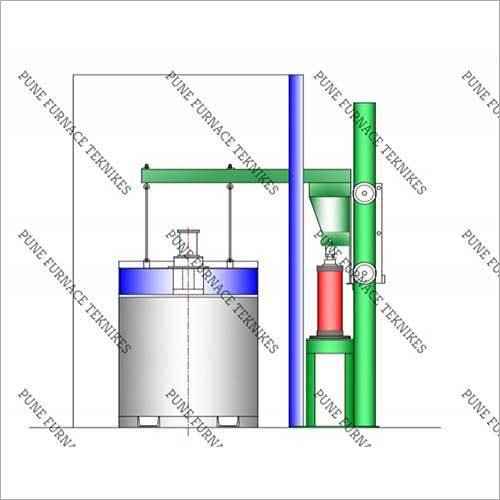

Ladle Preheater Furnace

Price 200000 - 30000000 INR/ Unit

Ladle Preheater Furnace Specification

- Feature

- Automatic temperature control, robust structure, efficient insulation

- Rating

- Up to 2500C operating temperature

- Condition

- New

- Type

- Fuel Fired Ladle Preheater Furnace

- Usage

- Preheating of steel ladles

- Power

- Depends on heater specification; up to 60 kW

- Voltage

- 415 V, 3 Phase, 50 Hz

- Size

- Custom sizes available as per ladle specifications

- Dimensions

- Depends on ladle size; standard and custom options

- Weight

- Varies with design; typically between 2 to 5 metric tons

- Application

- Metallurgical industry, steel plants

- Fuel Type

- Diesel, Furnace Oil, LPG, or Natural Gas

- Capacity

- Supports ladles ranging from 10 MT to 60 MT

- Insulation Type

- Ceramic wool and high alumina castables

- Control System

- Digital temperature controller with display

- Portability

- Available with wheels for easy movement

- Safety Standards

- Equipped with flame safety devices, over-temperature cut-off

- Material

- High-grade refractory lining and steel fabrication

- Mounting

- Mobile and stationary versions available

- Heating Method

- High velocity burners for uniform heating

- Service Support

- On-site installation and operator training

- Preheating Time

- 3060 minutes depending on ladle size

Ladle Preheater Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 15 Days

About Ladle Preheater Furnace

Ladle Preheater Furnace is used for metallurgic treatment, such as refining, adjustment of liquid steel temperature and chemical composition to increase the quality of steel. It is fabricated using superior quality raw materials at our well established manufacturing unit. The furnace is made in various sizes and specification on analysis of actual demand. We provide this Ladle Preheater Furnace at market leading prices.

Technical Details:

Material Loading Capacity | >5000 kg |

Max Temperature | 2000-2500 Degree Celsius |

Power Kw | Up to 15 |

Power Source | Electric |

Material of Construction | Stainless steel |

Automatic Grade | Automatic |

Uniform Heating with Advanced Burners

Fitted with high velocity burners, our Ladle Preheater Furnace achieves an even and consistent temperature distribution, minimizing hot and cold spots inside the ladle. This promotes more reliable steel processing and improves quality control during metallurgical operations.

Precision Control and Safety Features

A digital temperature controller with a clear display provides accurate heat regulation. Integrated flame safety devices and automatic over-temperature cut-off ensure a secure operating environment, safeguarding both equipment and personnel.

Customizable and Portable Solutions

The furnace can be tailored to fit a variety of ladle sizes and plant layouts. Portable models with heavy-duty wheels make movement and installation convenient, while stationary versions are suited for fixed operations. On-site installation and operator training ensure optimal utilization and low downtime.

FAQ's of Ladle Preheater Furnace:

Q: How does the high velocity burner improve the ladle preheating process?

A: High velocity burners enable rapid, uniform heating by circulating hot gases evenly throughout the ladle's interior. This technique minimizes temperature gradients and shortens preheating time, resulting in energy-efficient and consistent performance.Q: What safety measures are included in this furnace?

A: The furnace is equipped with flame safety devices and an over-temperature cut-off system. These features monitor burner operation, detect flame failures, and automatically shut down heating if unsafe temperature limits are exceeded, ensuring operational safety at all times.Q: When should I choose a mobile version over a stationary furnace?

A: A mobile furnace is ideal when ladle preheating needs to occur at multiple locations within the plant or facility. For operations where preheating is consistently done at a single station, a stationary model is more suitable.Q: Where is this Ladle Preheater Furnace most commonly used?

A: This furnace is widely utilized in the metallurgical industry, particularly in steel plants where efficient preheating of steel ladles is essential for production continuity and steel quality.Q: What is the process for installing and starting up the furnace?

A: The manufacturer provides on-site installation and operator training. After installation, the system undergoes commissioning with tailored setup for your specific ladle size and fuel type, followed by training for safe and efficient operation.Q: How does the insulation system benefit operational efficiency?

A: The use of ceramic wool and high alumina castables provides superior thermal insulation. This reduces heat loss, improves energy efficiency, and maintains stable high-temperature conditions during the ladle preheating process.Q: What are the benefits of having a digital temperature controller?

A: A digital temperature controller ensures precise temperature management, allowing operators to monitor and adjust heating as required. This leads to improved process control, reduced risk of overheating, and consistent ladle performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnaces For Aluminum Industry Category

Rotary Degasser Furnace

Price 200000 - 30000000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : Efficient hydrogen removal, uniform metal quality

Rating : High performance industrial grade

Fuel Type : Electric or gas

Single Tray Solution cum Aging Furnace

Price 200000 - 30000000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : Uniform Heating, Precise Temperature Control, Energy Efficient, Digital Controller

Rating : Industrial Grade

Fuel Type : Electric

Tower Melting Furnace

Price 200000 - 30000000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : Automatic control, Energy saving, Uniform melting

Rating : High efficiency

Fuel Type : Electricity, Oil, or Gas

Drop Bottom Furnace

Price 200000 - 30000000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Feature : Automatic door with hydraulics, precise temperature control, digital display

Rating : High efficiency industrial rating

Fuel Type : Electric/Gas

Send Inquiry

Send Inquiry